Tesla's global demand for skilled EV technicians drives innovative Structural Repair Training programs focusing on advanced metalworking and thermal management. Mastering these areas ensures top-quality repairs, preserving vehicle performance and integrity worldwide. Effective thermal control in EVs is crucial for long-term efficiency and structural integrity, reducing the need for intensive training while enhancing overall vehicle range. Integrating advanced cooling technologies contributes to a smoother transition to cleaner transportation.

“In the rapidly evolving landscape of electric vehicle (EV) technology, ensuring optimal performance and longevity requires specialized knowledge. This article delves into the critical aspects of Tesla structural repair training and thermal management preservation. As the demand for EVs surges, so does the need for a skilled workforce equipped to handle intricate repairs. We explore how comprehensive training programs are revolutionizing the industry, ensuring vehicles maintain peak efficiency, particularly in managing heat, a key factor in EV durability.”

- Tesla Structural Repair Training: Building a Skilled Workforce

- Unveiling the Importance of Thermal Management in Electric Vehicles

- Preserving Performance: Long-Term Strategies for Thermal Control

Tesla Structural Repair Training: Building a Skilled Workforce

Tesla’s commitment to advancing its electric vehicle (EV) technology has led to a growing demand for skilled technicians capable of handling complex structural repairs and thermal management systems. The company recognizes this need and has taken significant steps to address it through comprehensive training programs. Tesla Structural Repair Training is designed to build a highly skilled workforce, ensuring that repair shops and bodyshops across the globe can handle the unique challenges presented by these cutting-edge vehicles.

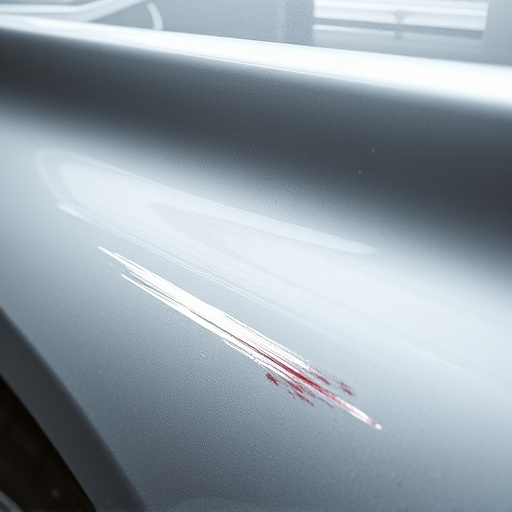

This training initiative focuses on educating professionals in the intricacies of car body repair, specifically tailored to Tesla models. It covers everything from advanced metalworking techniques to understanding the intricate thermal management systems within Tesla vehicles. By investing in auto detailing and car bodywork expertise, Tesla empowers its network of authorized service centers to deliver top-tier repairs, preserving the integrity and performance of these high-tech automobiles.

Unveiling the Importance of Thermal Management in Electric Vehicles

In the realm of electric vehicles (EVs), thermal management is a crucial aspect that often goes unnoticed until its absence causes significant issues. As Tesla structural repair training becomes increasingly vital, understanding thermal dynamics is at the core of ensuring long-term vehicle performance and longevity. EVs generate substantial heat during operation, particularly in their batteries and motors, which require efficient cooling systems to maintain optimal temperatures.

Effective thermal management not only preserves the integrity of the vehicle’s structure but also safeguards its sensitive components from extreme temperatures. This is especially pertinent in the event of car damage repair or auto collision center procedures, where proper thermal preservation techniques can minimize component degradation and reduce the need for extensive Tesla structural repair training. By embracing advanced cooling technologies and materials, EV manufacturers can enhance overall vehicle efficiency and drive range while ensuring a seamless transition to cleaner transportation solutions.

Preserving Performance: Long-Term Strategies for Thermal Control

In the realm of Tesla structural repair training, understanding thermal management is paramount to preserving performance over the long term. Electric vehicles, unlike their internal combustion engine counterparts, generate heat differently, requiring specialized strategies for efficient thermal control. This involves not just managing the battery pack and motor during operation but also ensuring proper preservation techniques for optimal longevity.

The art of thermal management in automotive repair, specifically tailored to Tesla’s advanced technology, encompasses various methods, from strategic material selection in paintless dent repair processes to intricate cooling systems design. By adopting these practices, professionals can ensure that vehicles not only meet original equipment manufacturer (OEM) standards but also maintain peak performance and efficiency for years to come, rivaling even the likes of Mercedes-Benz repairs when it comes to precision and durability.

In conclusion, investing in Tesla structural repair training and implementing effective thermal management strategies are vital steps towards ensuring the longevity and performance of electric vehicles. By fostering a skilled workforce through specialized training and adopting advanced preservation techniques, we can maintain the integrity and efficiency of these innovative automobiles, setting a new standard for the industry.